A framework for sustainable and circular system design: development and application on thermal insulation materials

Circular economy is increasingly promoted as a solution to decouple economic growth and environmental impacts. To design a circular and sustainable system, a structured approach is needed. In this study, we suggest to follow a 3-step approach. First, the status quo is evaluated using environmental assessment methods. We determine current circularity (share of assessed product and material retained and further used in the system), environmental impacts, the most impactful products and processes, and assess contaminants and impurities. Second, scenarios favoring circularity strategies are developed and their environmental impacts evaluated. Third, the scenarios are compared and measures for environmental impact mitigation derived.

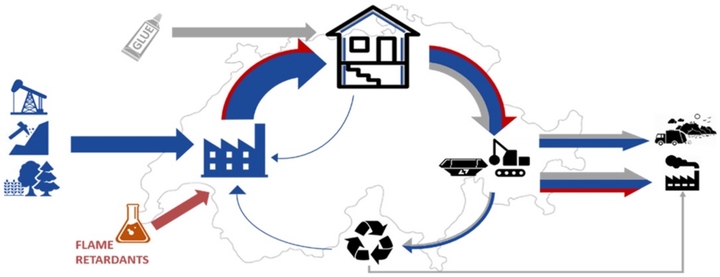

The suggested approach was applied to the case study of thermal insulation in residential buildings in Switzerland. Coupling dynamic, prospective material flow analysis with life cycle impact assessment enabled to determine current and future environmental impacts. Current material circularity is low due to lacking incentives for recycling and legally required incineration of flame retardant containing oil-based materials. The most impact-intensive processes were the production of insulation materials and the incineration of oil-based materials including their adhering residues. The investigated scenarios include (i) increased recycling, (ii) augmented use of biogenic materials, and (iii) a combination thereof. All scenarios lead to reduced climate change and human toxicity impacts. The second and third scenario showed increased impacts for land use, ozone depletion, and ecotoxicity. Taking into consideration end-of-life already in the design process, phasing out toxic materials, and increasing usage of renewable materials are crucial for sustainable, circular system design.