Material efficiency and its contribution to climate change mitigation in Germany: A deep decarbonization scenario analysis until 2060

Abstract

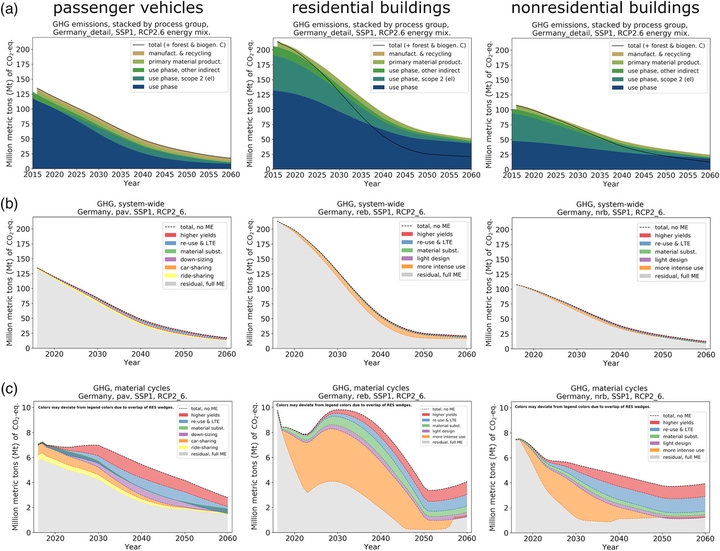

Germany’s greenhouse gas emissions have declined by 35% since 1990, and the national policy ambition is to become largely carbon‐neutral by 2050. A change of the industrial landscape and a partial transformation of energy supply have contributed to reductions so far, but for deep reductions, a deep transformation of the country’s industrial metabolism is needed. While energy efficiency is well established, the same cannot be said for material efficiency, which includes product light‐weighting, lifetime extension, more intense use, and value retention strategies like higher recycling rates, remanufacturing, and reuse. Sector‐specific research showed substantial energy and emissions savings potentials of material efficiency, but the overall material efficiency potential for most world economies, including Germany, is unknown. We applied an open‐source and modular dynamic material flow analysis model of the transformation of passenger vehicles, residential buildings, and commercial and service buildings in Germany (together ca. 50% of national greenhouse gases) to a material‐efficient system, covering the time span 2016–2060. The potential impact of the above‐mentioned material efficiency strategies was studied for the climate‐relevant materials concrete, steel, timber, aluminum, and plastics. Once the potentials of energy‐efficient products, electrification of end‐use sectors, and energy system transformation are seized, supply and demand side material efficiency and sufficiency can reduce remaining 2050 emissions by an additional 19–34 % (passenger vehicles), 27–31% (residential buildings), and 14–19% (non‐residential buildings). The 2016–2050 cumulative savings can be up to 750 Mt (million metric tons) CO2‐eq. Material efficiency can be a key contributor to deep emissions cuts like a 95% target.