Optimisation of energy-efficient greenhouses based on an integrated energy demand-yield production model

Abstract

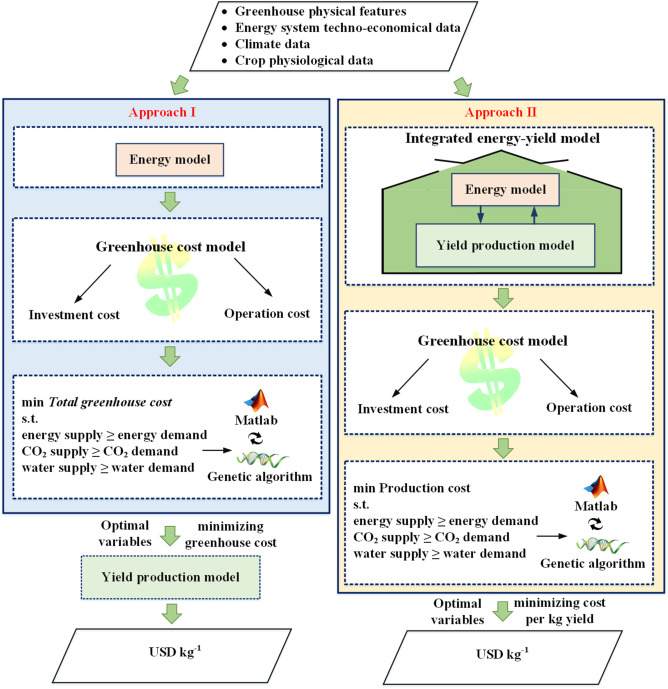

The aim of this paper is to develop a simulation framework to minimise the cost associated with commercial greenhouse yields (production cost). Greenhouse energy demand and yield production models are coupled with a cost model to investigate the interaction between energy consumption costs and yield production benefits. The coupled model is defined as an optimisation problem to determine the optimal values of decision variables (e.g. cover material, heating and cooling technology, inside temperature and relative humidity set points, plant density, etc.), which result in minimum production cost as the objective function. The results show that the integrated energy demand-crop yield production model outperforms the “classical approach” of a separate energy consumption model where yield is not explicitly modelled but only considered by constraints warranting good growing conditions. In the case of a tomato greenhouse in Iran, the financial cost and environmental impact of producing a 1 kg yield based on integrated energy demand-yield production model were 49% and 29% lower than the energy-consumption model alone. Moreover, the impact of fuel prices on the optimisation results is investigated by use of the proposed framework. Considering real fuel prices instead of current subsidised fuel prices in the Iranian case study, 70% of energy consumption and 19% of climate change impacts could be eliminated while increasing the production cost by 17%. Selling the saved fuel at real prices to other customers would provide the government with more than enough money to compensate the farmers for the increased yield cost.